A Z A Y A h v a c

Decorations interior design

HEATING - VENTILATION & A/C

ELECTRICAL - PLUMBING - COLD ROOM

Air Conditioners

The first modern air conditioning system was developed in 1902 by a young electrical engineer named Willis Haviland Carrier. It was designed to solve a humidity problem at the Sackett-Wilhelms Lithographing and Publishing Company in Brooklyn, N.Y. Paper stock at the plant would sometimes absorb moisture from the warm summer air, making it difficult to apply the layered inking techniques of the time. Carrier treated the air inside the building by blowing it across chilled pipes. The air cooled as it passed across the cold pipes, and since cool air can't carry as much moisture as warm air, the process reduced the humidity in the plant and stabilized the moisture content of the paper. Reducing the humidity also had the side benefit of lowering the air temperature -- and a new technology was born.

Carrier realized he'd developed something with far-reaching potential, and it wasn't long before air-conditioning systems started popping up in theaters and stores, making the long, hot summer months much more comfortable

How Air Conditioners Work

Air conditioners use refrigeration to chill indoor air, taking advantage of a remarkable physical law: When a liquid converts to a gas (in a process called phase conversion), it absorbs heat. Air conditioners exploit this feature of phase conversion by forcing special chemical compounds to evaporate and condense over and over again in a closed system of coils.

The compounds involved are refrigerants that have properties enabling them to change at relatively low temperatures. Air conditioners also contain fans that move warm interior air over these cold, refrigerant-filled coils. In fact, central air conditioners have a whole system of ducts designed to funnel air to and from these serpentine, air-chilling coils.

When hot air flows over the cold, low-pressure evaporator coils, the refrigerant inside absorbs heat as it changes from a liquid to a gaseous state. To keep cooling efficiently, the air conditioner has to convert the refrigerant gas back to a liquid again. To do that, a compressor puts the gas under high pressure, a process that creates unwanted heat. All the extra heat created by compressing the gas is then evacuated to the outdoors with the help of a second set of coils called condenser coils, and a second fan. As the gas cools, it changes back to a liquid, and the process starts all over again. Think of it as an endless, elegant cycle: liquid refrigerant, phase conversion to a gas/ heat absorption, compression and phase transition back to a liquid again.

It's easy to see that there are two distinct things going on in an air conditioner. Refrigerant is chilling the indoor air, and the resulting gas is being continually compressed and cooled for conversion back to a liquid again. On the next page, we'll look at how the different parts of an air conditioner work to make all that possible.

Evaporator - Receives the liquid refrigerant

Condenser - Facilitates heat transfer

Expansion valve - regulates refrigerant flow into the evaporator

Compressor - A pump that pressurizes refrigerant

HEAT RECOVERY VENTILATION

UNITS - HOW IT WORKS ?

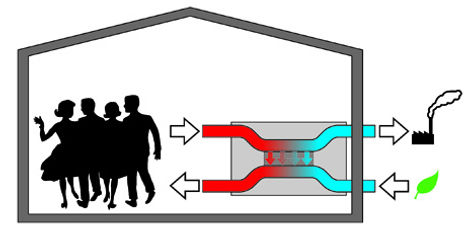

A heat recovery ventilation unit provides a clean, fresh environment in your home. It delivers fresh filtered air from outside the building to the living and bedrooms and extracts stale air from high moisture areas such as bathrooms, kitchens and laundries. At the same time it recovers up to 95% of the heat from the exhaust air and transfers it to the incoming air. With a heat recovery ventilation unit you can maintain a high air quality without excessive additional energy costs.

Integrated humidity sensors constantly monitor the relative humidity in the rooms and the air volume supplied to the house is automatically adjusted until an adequate air quality is obtained. A Dantherm heat recovery ventilation unit will provide continual clean air with a minimal heat loss.

The benefit is increased comfort and big energy savings!

The heat exchange takes place in the counterflow heat exchanger. It consists of two separate, isolated air flows. One air flow is connected to the outdoor air and the other is connected to the extract air - in a way that the air flows are never mixed. Up to 95% of the heat from the extract air will be recovered and transferred to the incoming outdoor air, thus reducing energy bills, and making it a worthwhile investment

VRV or VRF ?

What’s the difference between VRV and VRF?

Many people who ask this question, mistakenly interpret it as 2 different HVAC technologies. Actually, those are two different terms for the same type of HVAC technology. Based on Inverter technology compressors, the first VRV HVAC systems were invented by Daikin during the early 1980’s. As a technology leader in the HVAC industry, Daikin had registered the VRV term (which stands for Variable Refrigerant Volume1) as an official trademark. All other companies use VRF (Variable Refrigerant Flow2) for their similar HVAC systems. Eventually, VRF is the more common term for these types of systems, and this is the term that will be used for the rest of the article.

So what is VRF?

VRF can easily be related to as the “Rolls Royce” of Air Conditioning Systems. It’s a very sophisticated technological air conditioning system, based on several principles:

-

Refrigerant only – where refrigerant is the only coolant material in the system (in contrary to the chilled water systems, where refrigerant is used for cooling/heating the water that is circulated throughout the whole system).

-

Inverter compressors that allow lowering power consumption with partial cooling/heating loads.

-

Several air handlers (indoor units) on the same refrigerant loop / circuit.

-

Ability of modular expansion (especially applicable for large projects, that can grow in stages).

Typical VRF system structure

A typical system consists of an outdoor unit (comprising one or multiple compressors), several indoor units (often and mistakenly called “fan coils”), refrigerant piping, running from the outdoor to all indoors, using Refnet Joints (copper distributors in pipes) and communication wiring.

CHILLED WATER SYSTEM WORK

Although standard air conditioners are very popular, they can use a lot of energy and generate quite a bit of heat. For large installations like office buildings, air handling and conditioning is sometimes managed a little differently.

Some systems use water as part of the cooling process. The two most well-known are chilled water systems and cooling tower air conditioners.

Chilled water systems - In a chilled-water system, the entire air conditioner is installed on the roof or behind the building. It cools water to between 40 and 45 degrees Fahrenheit (4.4 and 7.2 degrees Celsius). The chilled water is then piped throughout the building and connected to air handlers. This can be a versatile system where the water pipes work like the evaporator coils in a standard air conditioner. If it's well-insulated, there's no practical distance limitation to the length of a chilled-water pipe.

COLD ROOM WORK

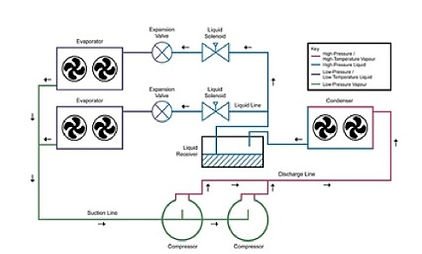

There are various refrigeration mechanism and processes but Vapour Compression Refrigeration System is the common one. Cold storage plant also works on the 'Vapor Compression Refrigeration' cycle. The second law of thermodynamics (Clausius statement for a heat pump) is the basis of cooling. As per the second law, in order to transfer heat from low-temperature body to high-temperature body, one needs to put extra energy. Compressor power is work or energy needed for cooling process continuation.

Compressor: Compressor is the heart of the cold storage plant and only power consuming device or machine of the cold storage plant. The majority of power is consumed by the compressor. It raises the temperature and pressure of refrigerant (the working medium, Ammonia) vapor coming out from an evaporator. Due to high pressure, the refrigerant boiling point gets increased and thus it can be now easily condensed at condenser temperature.

Condenser: It is a heat exchanger device which exchanges the heat from vapor refrigerant and water being circulated. The condenser is not power consuming device. It condenses (meaning 'phase change') the high-pressure and high-temperature refrigerant to the high-pressure and high-temperature liquid. One can say, a condenser is a heat sink where heat is rejected.

Receiver: It receives the high-pressure liquid condensate from the condenser and collects it.

Expansion Valve: It reduces the pressure and temperature of refrigerant from receiver pressure and temperature to evaporator pressure and temperature. The throttling process makes the pressure and temperature reduction. Due to friction, throttling process occurs and pressure along with temperature decreases.

Evaporator: The heat exchanger where actual cooling takes place. It evaporate (vaporize) the low-pressure, low-temperature liquid refrigerant (with low boiling point) by taking/utilizing heat from atmosphere/storage compartment to be cooled, thus heat content of fruits or vegetable decrease and it cool due to this cyclic process (Chilled air is produced due to convection current)

Blowers: It circulates chilled air in the refrigerated space to cool the fruits and vegetables by convection process.